|

PPS Prefabricated Plaster System Convert your wall to a Light Weight Concrete Wall

If you are tired of wooden products with insects and fire problems, if you are tired of the all temporary type building appearance, if you want that building looks like all other buildings, if you want to have a hard wall feeling while you are hitting the wall, if you became tired of the cracks in the wall, then you have come to the right place! PPS Prefabricated Plaster System is developed for plastering of the conventional prefabricated buildings cover materials.

|

|

|

|

Click for Application Procedure

|

|

|

|

|

|

|

|

PRODUCT FEATURES Soundproof: Provides a high level of sound insulation thanks to its acoustic properties. Can be used for indoor locations such as neighboring walls, apartment block and elevator shafts, offices, hotels, theaters and conference halls. Heatproof: Delivers a high level of heat insulation like a blanket thanks to its porous structure in the mixture. Waterproof: Make a barrier against water and humidity effet. Fire-resistant: Make a barrier to fire with its A1 class fire resistance. Economic: Saves labor up to 30% since it is easily applied and dries slowly. And covers a 40% larger area compared to other products, thanks to its porous structure and low density. Green: Contributes greatly to the achievement of the criteria of the green building rating system (LEED). Environmentalist: An environmentally friendly product with no harm on human health. Resistant: as a result of its flexibility & rigidity, it does not crack. With PPS magical composite system you can have a rigid plaster which is durable against simple deflections. It creates also a strong bond thanks to its high level of adhesion and endurance.

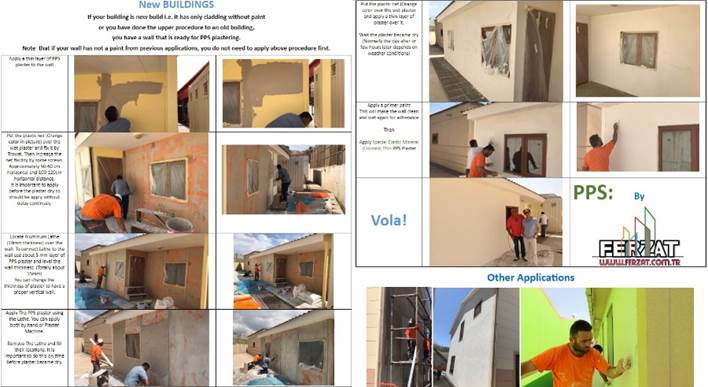

APPLICATION The application surface should be clean, dry and strong (All residues that may prevent adhesion such as dust. din. oil em. and loose particles should be removed). Cracks and broken areas. If any, no need to be repaired before the application. Unlevelled surfaces. No need to take any care. Can be levelled by plaster application Add 10 kg of PPS plaster into 10 kg of water in a mixture container. Ensure that the mixture is fully. the water. Wait for 3-5 minutes and. then mix it for at least 5 minutes until a homogenous mixture Is formed The package content should he completely used to make the product fudy homogenous Applicable can be applied on Concrete. Exposed Concrete. Gas Concrete. Pumice Concrete. Brick Rough Cast and Piaster Board Surfaces. Make sure that the plaster Is equally spread on the surface by means of a suitable plaster machine. It is recommended to use alignment ban Spread the product during the first application You may carry out additional layer/ layers after it dries. Strike off the surface after the application. and correct it by means ot a suitable trowel incase of holes an the surface.

STORAGE CONDITIONS Not more Nan to bags should be stowed one on the top of the other. May be stored up to 1 year on the condition that the bags are stored on a palette. Store materials off the ground protected from moisture and dampness

TECHNICAL SPECIFICATIONS Fireclass :A1 Thermal conductivity :0.110 Vapor permeability :5 Compression strength :0.25 Water absorption :5% Hardening time :8 hours Consumption fora thickness of 1 cm : about 5.5-6 m2

|

||